How Minitab HelpedĪfter collecting downtime data based on medical equipment type and cause of equipment failure for each hospital, the project team used Minitab to identify the equipment types with the highest percentage of downtimes and the most common causes for those downtimes.ĭisplaying the data using Pareto charts showed the team that the majority of downtimes were caused by electrical issues, and the percentage of faults was highest among diagnostic and life support machines. Ultimately, the team wanted to improve repair procedures to make equipment more readily available and ensure that patients promptly received life-saving treatments. Working within the Six Sigma project framework called DMAIC (for Define, Measure, Analyze, Improve, and Control), the project team’s challenges included identifying reasons for variation in equipment downtime so they could focus their efforts where they would make the biggest difference. Using the knowledge they acquired by collecting data and analyzing it with Minitab Statistical Software, the team has implemented a new equipment maintenance procedure that’s making a difference in ensuring critical equipment is working and ready when it’s needed. But a recent healthcare quality project shows how an important tool that’s still new in many facilities-data analysis-can help hospitals ensure that doctors have the equipment they need to serve their patients.Ī Lean Six Sigma team in Amman, Jordan, examined the factors affecting equipment downtime, and identified elements of the maintenance process that could improve equipment availability. When essential medical equipment is unavailable due to repairs, a doctor’s ability to save lives is diminished. But that remedy alone can’t save a patient unless the doctor also has access to the tools and equipment needed to deliver the recommended treatment. Coming back to the question of identifying the top defect categories that contribute to almost 80% of all the defects.When treating patients, doctors use their own experience, the combined knowledge of their colleagues, and the latest advances in medicine and technology to identify the best course of action. So if we focus on these 20% causes, you really can focus improvement efforts on areas where the largest gains that is 80% gains can be made. Similarly 80% of the problems are due to 20% causes. It says that 80% of the world's wealth is with 20% individuals.

In a nutshell, a Pareto chart is based on the 8020 principle.

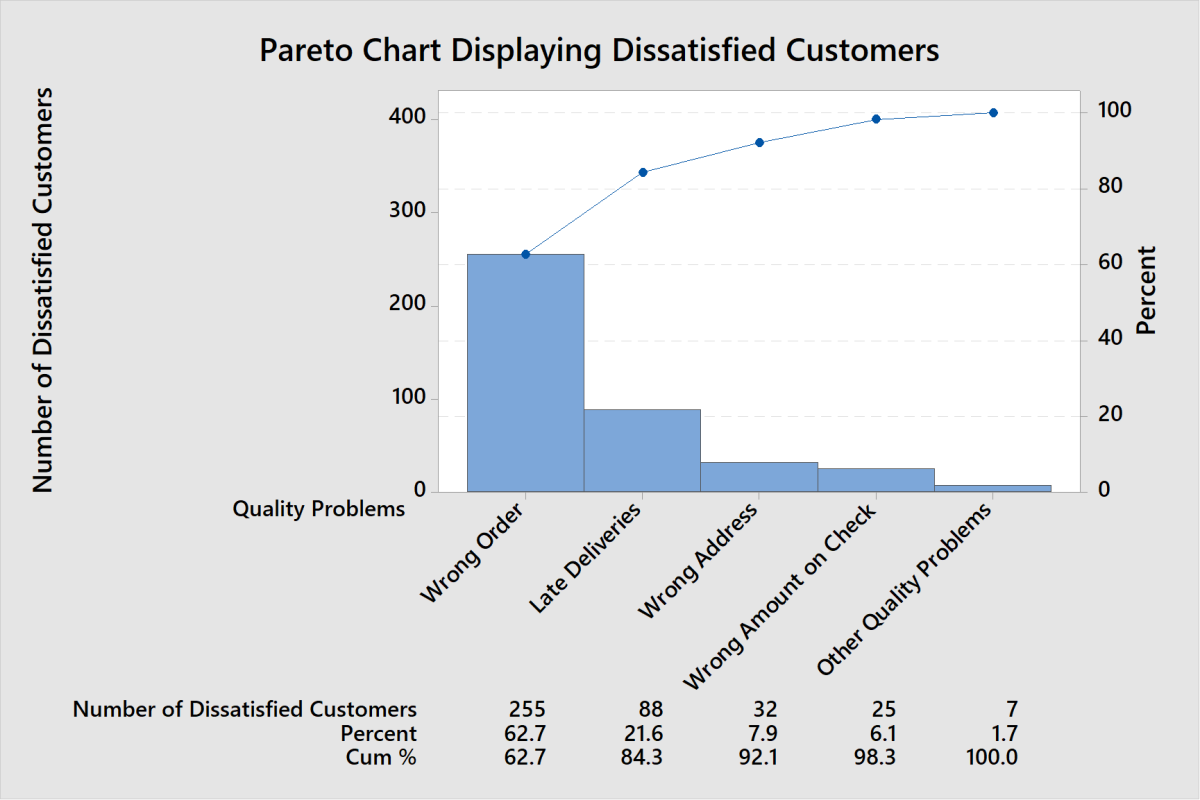

A Pareto chart can help to focus improvement efforts on areas where the largest gains can be made. A cumulative percentage line helps you judge the added contribution of each category. The categories are often defects by ordering the bar from largest to smallest, a Pareto chart can help you determine which of the capture defects comprise the vital few and which are the trivial many. A Pareto chart is a type of a bar chart in which the horizontal axis represents categories of interest rather than a continuous scale.

In this situation, a Pareto analysis or a Pareto chart will come in very handy. Use a suitable analysis to identify which are the top two to four defect categories that are contributing to almost 80% of the total number of defects. The defects data is added to a spreadsheet and uploaded in the resources section of the next lecture. The operations team has gathered data to capture defects during the manufacturing process. What is a Pareto chart? Let's say you are working for an organization that manufactures toy cars.

0 kommentar(er)

0 kommentar(er)